The bimetallic thermometer is an instrument designed to measure temperature based on the principle of thermal expansion of different metals; let’s examine its principles of operation.

The concept of the bimetallic thermometer emerged in the 19th century, in parallel with advancements in thermodynamics and material science; using two metals with differing thermal expansions offers a simple and reliable way to measure temperature without the need for complex electronics. This aspect makes the bimetallic thermometer an ideal tool in industrial settings, where robustness and ease of use are crucial.

As the name suggests, the operation of bimetallic thermometers relies on the fact that various metals have different coefficients of thermal expansion.

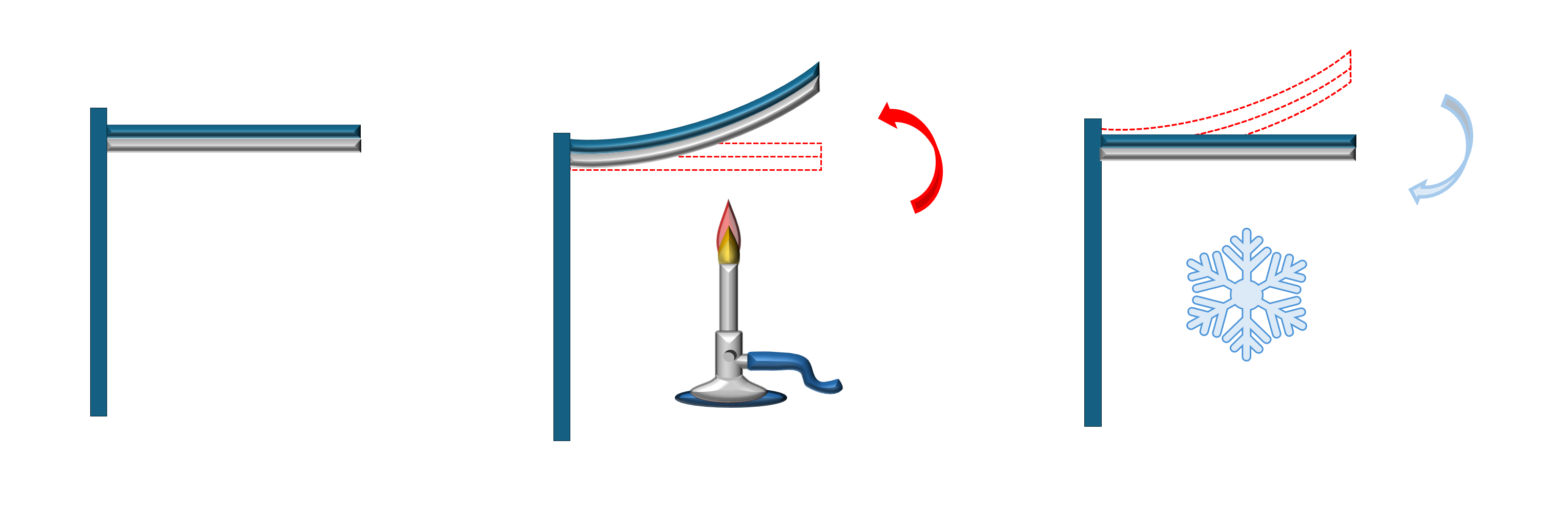

Thermal expansion is a physical phenomenon where a metal changes its dimensions (length, area, or volume) in response to temperature changes; this occurs because an increase in temperature provides thermal energy to the metal’s particles, causing them to vibrate with greater intensity. As a result, the average distance between particles increases, leading to a physical expansion of the material; similarly, a decrease in temperature leads to the contraction of the material. This process is thus reversible, meaning that the metal can return to its original dimensions if the temperature returns to its initial value.

The change in dimensions due to temperature depends on various factors, including the type of metal and its coefficient of thermal expansion, a numerical measure that indicates how much a particular metal expands for each degree of temperature increase; for example, given the same temperature difference and initial length, aluminum expands twice as much as iron.

This phenomenon is exploited in the bimetallic strip, consisting of two strips of different metals, welded together: one end of the strip is fixed, and the other end is free. At room temperature, the two metals are of equal length, but when the strip is heated, the aluminum elongates more than iron, causing the strip to bend.

In general, a material lengthens when heated and contracts when cooled: the behavior is approximately symmetrical.

The bimetallic strip is highly sensitive to temperature variations; thus, it’s possible to construct a thermometer by utilizing the difference in expansion of the two metals.

In bimetallic thermometers, the two metal strips, usually steel and copper or steel and brass, depending on the measurement range, are welded or bonded together to form a spiral or a helical coil, which is placed inside the thermometer’s bulb. One end is fixed to the tip of the bulb while the other end is connected to a pointer, allowing the needle to move. When the temperature rises, the spiral deforms, and the pointer moves along the graduated scale; when the temperature decreases, the spiral returns to its original state, bringing the pointer back to its initial position.

Since bimetallic thermometers use common metals and simple mechanical technology, they are among the least expensive industrial thermometers available. The versatility of the bimetallic thermometer is one of its greatest strengths. Thanks to its simple structure and low cost, it’s used in a wide range of applications. Additionally, its ease of installation and maintenance makes it a popular choice for many companies seeking reliable and long-lasting solutions. With its resistance to challenging conditions, such as extreme temperatures and vibrations, the bimetallic thermometer is a robust and effective choice. Compared to more complex thermometers requiring electronic components or external power, the bimetallic thermometer offers a straightforward and traditional method for measuring temperature. This makes it ideal even in situations where using electronic devices isn’t feasible or practical.