In the vast landscape of industry, the precision of pressure measurements is crucial to ensuring the proper functioning of processes and the safety of installations. Pressure gauges are indispensable tools for monitoring fluid pressure in various industrial environments, from chemical processes to energy production, from the food sector to industrial automation. However, to ensure the reliability of measurements, it is essential that pressure gauges are securely and accurately connected to piping systems. This is made possible through the use of specially designed fittings, which can be equipped with different types of threading. Among the most common threads are those governed by two series of standards: National Pipe Thread (NPT) and British Standard Pipe (BSP). In this article, we will examine both options in detail, providing a comprehensive overview of features, applications, and considerations for the installation of industrial pressure gauge fittings.

Brief history of pipe fitting standards

From the late 1700s to the mid-1800s, the industrial revolution was a catalyst for the establishment of standards across all sectors; in the realm of screws and fittings, as parts were manufactured and shipped to different parts of the world, a standard for threading became necessary to avoid incompatible parts.

In 1841, British engineer Joseph Whitworth created a threading model that was adopted by many British railway companies and quickly became the standard for all screw threads in the UK; this standard was widely used in the UK and the United States but not universally accepted. In 1864, American engineer William Sellers introduced his own threading design to end the widespread incompatibility among American manufacturers, and since his standard was used for railway work under government contracts, it soon became the US standard for screw threads. Whitworth and Sellers were thus the respective originators of the BSP and NPT pipe threading standards.

The geographical origin of a piping system or its parts still determines the type of threading used; manufacturers based in the United States and Canada adhere to the NPT standard, while those in most of the rest of the world adhere to the BSP standard.

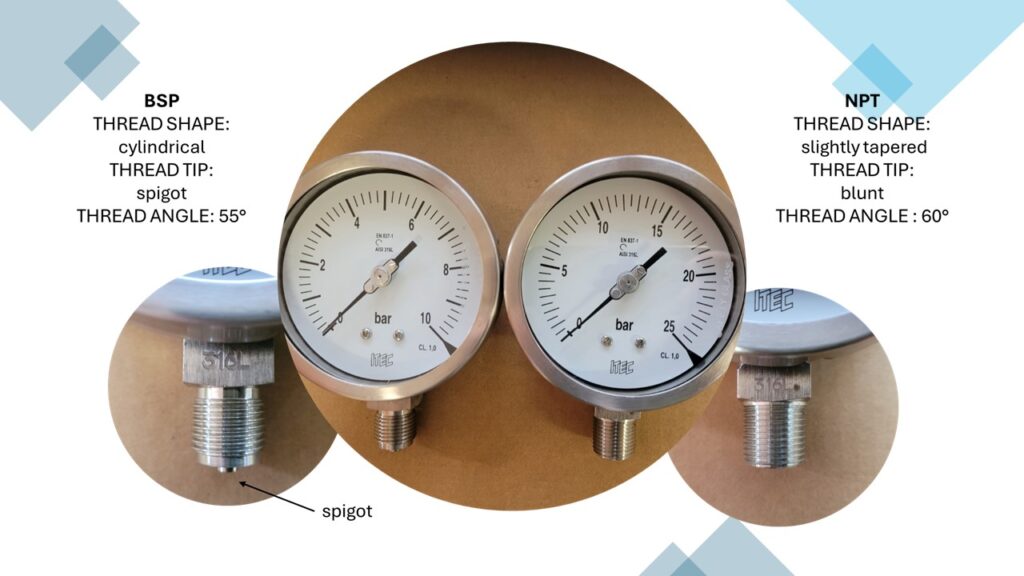

NPT Fittings

NPT male (external) fittings are slightly tapered and characterized by 60-degree thread angles and blunt backgrounds. The tapered structure causes the threads to narrow as they screw into the pipe, thus, to create a good seal, the use of a sealant such as PTFE tape is necessary. The tapered structure of NPT threads allows, during installation, for the connection to continue rotating a few more degrees after sealing, until the instrument reaches the desired position; however, in applications requiring regular installation and removal of the pressure gauge, this operation must be carried out with great care as excessive tightening could damage the threads and excessive compression could lead to friction.

The National Pipe system also includes parallel threads (National Pipe Straight Mechanical); however, this type of threading is typically found as a female (internal) component in non-pressurized devices such as thermowell.

BSP or GAS Fittings

BSPP (British Standard Parallel Pipe) fittings, often referred to as metric connections as they are used in the metric system, are characterized by a cylindrical body and parallel threading with 55-degree angles whose main function is to contain pressure, allowing for regular installations and removals of the instrument without the risk of damaging the threading and without the need for any sealant. However, to ensure the seal, a gasket inserted between the male fitting and the face of the female fitting and fixed in position is necessary, for this reason, the GAS connector ends with a small protrusion, called a nipple, used to center the gasket. Once the connector has reached the bottom of the threading to create the seal, the position of the instrument cannot be changed. To avoid the problem of inconvenient positioning of the instrument, a “crush washer” can be used and the fitting manually tightened.